How it Works

HoloLab obtains recycling data from many sources and shows it in a comprehensive portal. Learn about its amazing features.

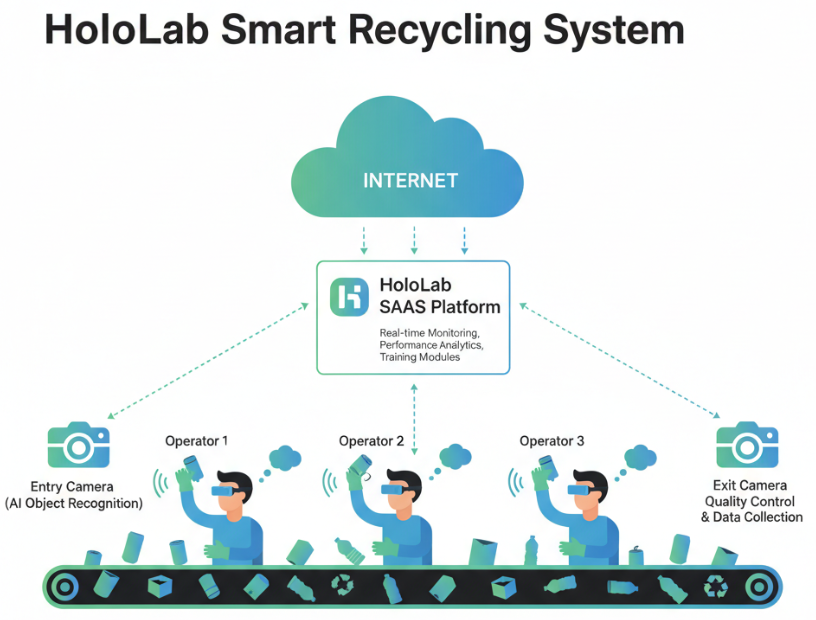

Uses cameras in recycling plants (in fact anywhere!)

HoloLab uses cameras at the start and end of the conveyor belt in recycling plants. These count the number of products that could be recycled and that were in fact. An advanced 2 layer AI system is able to accurately spot products. These are then shown in the HoloLab portal, along with data, location, and many more critical metadata.

This is a real video from a recycling plant near London where they have HoloLab installed. HoloLab is primarily designed to work on recycling plants, but it can in fact work anywhere: supermarkets, warehouses, stores....any place where cameras can be installed, monitoring products as they enter and exit the production line

Know how much you are effectively recycling

Unitl now, markets has relied on very rough numbers to know how much is being recycled. HoloLab comes to fill in that gap, identifying every single product which could be recycled and which effectively was. No more guessing on how to increase recycling and thus profits!

A new market: consumer product data

Imagine discovering that a recycling plant processes one million bottles of a particular cola brand every month. This insight is highly valuable for the manufacturer, and even its competitors, because it reveals that the product is being widely purchased and consumed within the plantís catchment area

Obtains data from operatives though headsets

Besides cameras on recycling plants, HoloLab also uses headsets worn by operatives. HoloLab then tracks how much each one recycles. This number is then compared with the amount of recyclable items found and left as seen by the cameras at the start and end of the conveyor belt. This is a real video from an operative at a plant currently using HoloLab, where we can see what he sees, what he is picking, and the data being captured and sent to the cloud in real time

This data is also used to compare it to TeknTrash Robotic's ALPHA robots: the world's first humanoid robot created especifically to work on recycling plants. For their performance in, for example, picking objects from the conveyor belt, can be compared with the ones obtained from HoloLab. The end result is that ALPHA can deliver results that are equal or best than humans, with the advange of being performed by robots, which can work 24x7, never get sick, etc

Know how much each operative recycles

HoloLab monitors operatives in their everyday work, counting the number of items picked and comparing it with the number of products found and left. This allows for a granular tracking of operatives performance

Increase recycling

HoloLab compares the items found, left, and actually picked. These numbers are then used to improve recycling ratios and thus profits at recycling plants. In fact, at any place where recycling is being actively performed, such as large corporations

AI monitors your recycling ratios in real time

HoloLab allows for real time monitoring on the amount of products recycled. This allows for changes to be applied immediately, thus avoiding losses and increasing profits. For that, HoloLab employs a dual layered AI system to identify recyclable items. This allows for a much more precise identification than regular systems

This is a video of a real setup deployed at a major recycling plant in UK. It shows how products are identified, processed, inserted in databases... and all in real time!

Monitor in real time

Waste identification is hard: products are dirty, crushed, partly covered, missing parts... HoloLab compensates this by first identifying areas in the video, and then locating products in them. The end result is a system which provides accountable data, with more products identified, and less false positives. Which ultimately means more sales

Export data

Export HoloLab's data to import it into CRMs, financial systems, etc, create dashboards, and much more. All these tools allow for a level of granularity unheard in the industry until now. Which in turn means knowing exactly what, where, when, how are needed to increase recycling and thus profits